To understand what a float type steam trap is, we need to understand what a “steam trap” is.

Steam, or vapor formed when water is heated to boiling point, is extremely useful with numerous industrial applications in heating and powering equipment. However, steam will lose energy through radiant heat loss which results in condensation (i.e. what water vapor begins to turn into liquid water).

This condensate that forms in high pressure steam pipelines reduces the steam’s efficiency to power and heat equipment, and can also cause significant equipment damage if it is not separated from the main process steam, also called the “live steam”.

The steam trap is essentially an automated valve that separates condensate, and other Non Condensable Gasses (NCG’s) from the live steam.

A float type steam trap is a type of steam trap that employs a closed spherical float with the function of holding back steam and discharging or “purging” the condensate and NCGs in pipelines.

As steam flows in pipes, the high rate of radiant heat loss causes condensate formation. The condensate is progressively carried by the steam, and causes a phenomenon known as rippling: a series of waves characterized by a knocking sound when steam hits a barrier.

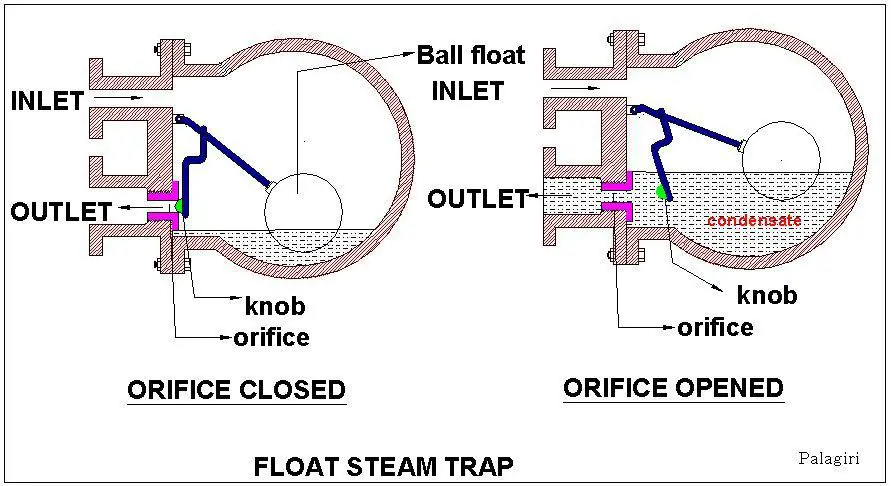

Since condensate is denser than steam, it collects at the base of the steam trap. After a period of time, the level of the condensate increases, and as a result, the knob or ball-float rises.

This places the discharge valve at a level that allows the condensate to pass smoothly when entering the trap. The outlet (discharge valve) is set above the condensate level to create a seal against steam loss. These traps are designed to allow continuous drainage.

For this reason, a float-type steam trap is perfect for heating applications. The discharge flow harmonizes with the condensing rate, and it’s not affected by slight pressure changes.

A free float steam trap is commonly used as the first choice to remove condensate from steam distribution pipes, steam using equipment (e.g. steam turbines), and temperature tracing applications (e.g. oil heat tracing).

Steam is produced using steam boilers which may be oil, coal, or gas. It may be used in several applications, for example, as the primary mover of turbines for internal power generation in factories and as a soot blower in coal boilers in industries.

As steam is distributed through pipes to these steam-using-equipment, condensate may form either in the distribution pipelines or the equipment. If that happens, float type steam traps may be used to remove it.

On the other hand, steam tracing is used to prevent the freezing of products such as oil during transportation in pipelines, especially during winter. Steam lines are used to carry steam along the product pipe. For example, steam tracing may be used to heat and reduce the viscosity of oil to ensure it flows smoothly at a constant rate.

Steam traps can be put into three categories; Thermostatic, Mechanical, and Thermodynamic. Each of these uses a unique principle to separate non-condensate and condensate gasses while retaining the steam.

Condensate is pure water. It has low mineral content and is used in a wide range of applications such as cooling towers.

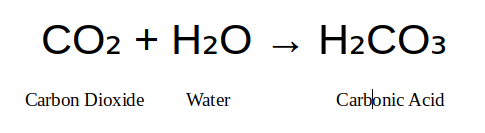

Low pH in the condensate is primarily caused by Carbon Dioxide (CO2). Carbon dioxide will enter the system if there’s an air leak and react with water to form carbonic acid, which is similar to acidic rain, as the steam condenses.

Stainless steel is the best material for setting up condensate systems. Stainless steel is able to withstand corrosiveness and it has a longer and more reliable life.

A mechanical steam trap is a trap that operates on the principle of difference in density between condensate and steam. Condensate is approximately 1500x denser (heavier) than steam. Therefore it will collect at the base of the trap.

This base is connected to an outlet or discharge valve and there’s a float that moves up and down, hence regulating the opening and closing of the valve. The main advantage of mechanical steam traps is that external factors do not affect them.

This is unlike thermodynamic and thermostatic types, whose efficiency can be altered by factors such as wind and rain.